Superior Storage Solutions by FRP Mocoat Fiberglass

Double-wall fiberglass tanks are essential for safely storing corrosive, hazardous, and environmentally sensitive substances. In Washington, industries facing strict environmental and safety regulations turn to these tanks as a dependable solution. Designed to prevent spills that could harm public health or the environment, double-wall FRP tanks act as a robust line of defense against leaks and failures.

Compliance and Confidence in Washington

As Washington’s environmental standards continue to evolve, the demand for double-wall fiberglass tanks has increased. These tanks are frequently required for underground and hazardous material storage due to their ability to provide dual containment. This added layer significantly lowers the risk of leaks, ensuring full compliance with local and federal laws.

Key Industries Utilizing Double-Wall FRP Tanks in Washington

- Chemical Manufacturing: Chemical producers rely on double-wall FRP tanks to safely store volatile substances and prevent accidental releases.

- Processing Facilities: From pharmaceuticals to food and petrochemical production, these tanks ensure safe containment and regulatory adherence.

- Water Treatment Plants: To handle treatment chemicals without risking contamination, municipalities and private facilities use double-wall fiberglass tanks for secure storage.

Why Choose Double-Wall Fiberglass Tanks?

FRP Mocoat Fiberglass offers a wide range of benefits for Washington-based businesses:

- Enhanced Safety: Dual-wall construction provides extra containment, protecting personnel and the surrounding ecosystem.

- Corrosion Resistance: Unlike steel, fiberglass does not corrode, making it ideal for long-term use with aggressive chemicals.

- Environmental Protection: The interstitial space acts as a safeguard, catching leaks before they escape into the environment.

- Regulatory Compliance: Our double-wall FRP tanks meet Washington’s stringent storage regulations.

- Long-Term Value: These tanks offer unmatched durability with minimal maintenance.

- Custom Configurations: Available in multiple sizes and designs to fit the unique storage needs of Washington industries.

Easy Installation & Low Maintenance

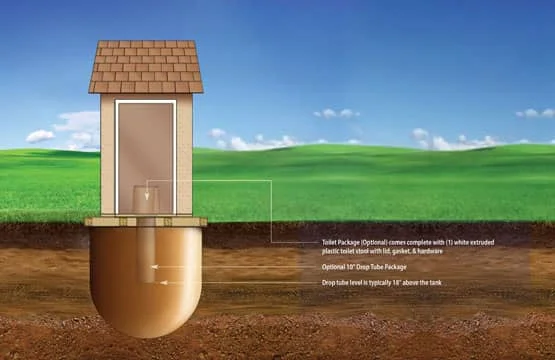

Installing a double-wall fiberglass tank from FRP Mocoat Fiberglass is simple. These tanks are placed on a level surface and come with complete guidance for quick setup. Maintenance is minimal – routine inspections and basic cleaning help ensure ongoing performance with little downtime.

Serving Washington with Trusted Engineering

FRP Mocoat Fiberglass delivers expertly engineered double-wall FRP tanks to clients across Washington. Our design process includes AutoCAD drawings tailored to your requirements, supported by licensed engineering sign-off. Every tank is tested – both primary and interstitial layers – ensuring total safety and performance.

Ready to Order in Washington?

If you’re based in Washington and need a reliable solution for storing hazardous or sensitive materials, FRP Mocoat Fiberglass is ready to assist. Whether you need an above-ground tank, underground tank, or custom-built solution, our team ensures fast, compliant, and cost-effective service.

Contact us today to speak with a local representative or request a custom quote. Your solution starts here.

Frequently Asked Questions

What type of tanks provide an extra layer of protection against leaks and spills?

Double-wall fiberglass tanks are designed to include two layers of containment, offering enhanced protection against leaks and spills. This makes them ideal for use in Washington, where environmental safety and regulatory compliance are key concerns.

What are the benefits of using a storage tank with two layers of protection?

A double-wall FRP tank provides numerous advantages for Washington-based industries, including superior leak prevention, safer chemical containment, and adherence to the state’s strict environmental regulations. The interstitial space between the walls enables effective monitoring for added safety.

Which material is commonly used in the construction of long-lasting, corrosion-resistant storage tanks?

Fiberglass is widely used for its non-corrosive properties and strength. In Washington’s industrial environments, fiberglass construction ensures durability, longevity, and reduced maintenance for storage tanks that handle harsh or hazardous substances.

Which storage solution offers superior durability and resistance to corrosion?

For maximum durability and corrosion resistance, double-wall fiberglass tanks from FRP Mocoat Fiberglass are the top choice. They outperform steel and concrete alternatives, making them especially suited to the demands of Washington’s industries.

How do I order double-wall fiberglass tanks in Washington?

To order double-wall fiberglass tanks in Washington, contact FRP Mocoat Fiberglass directly. Our team will work with you to design a tank that meets Washington’s environmental and engineering standards.

What type of tank is recommended for industries with strict regulations regarding hazardous substance storage?

Industries operating under Washington’s stringent hazardous material regulations are best served by a double-wall FRP tank. These tanks ensure full containment, easy monitoring, and compliance with local and federal guidelines for chemical and waste storage.