Features & Benefits

Home » Buildings & Shelters » MV – Vaulted Roof Style » Features & Benefits

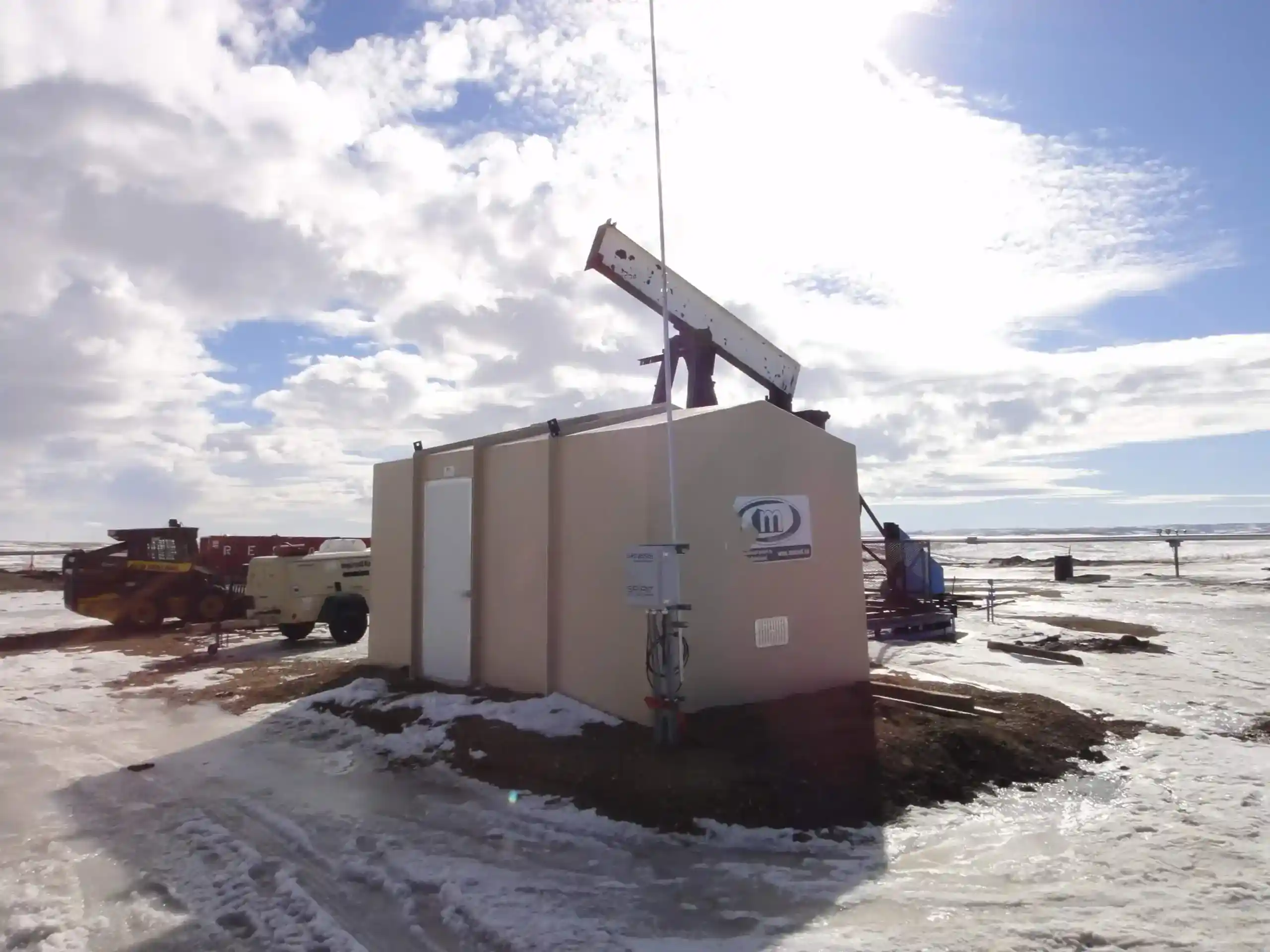

- Ease of Handling: FRP/Mocoat vaulted roof buildings come equipped with steel lift lugs and are manufactured with a high strength to low weight ratio, making it easily portable and durable.

- Resistance to Corrosion: Fibreglass building shells are weather, mould and mildew resistant. non-corrosive, chemically resistant and UV protected. This feature makes our buildings perfect for sweet and sour applications.

- Virtually Maintenance Free: Fibreglass building shell is weather, mould and mildew resistant, non-corrosive, chemically resistant and UV protected. Cleaning is easy as the building is spray washable inside and out. If repair is necessary, the process is simple and requires no expertise.

- Double-wall construction: “All wellhead shelters are not created equal”. All FRP/Mocoat fibreglass buildings and wellhead shelters are constructed with a double-wall system to provide superior strength and durability.

- Protection: Besides its resilience our double wall system also helps protect the foam insulation from deterioration, delamination, rodents and other problems associated with exposed insulation.

- Adaptability: FRP/Mocoat shelters are easily installed over existing piping. The most common method is to cut a slot in the building with a slight miter end. Once the shelter is placed over top of the wellhead or process equipment, the area removed from the slot should be cut underneath the piping and then reinstalled into place using either caulking or sheet metal and self-tapping screws.

- Pre-engineered design: Our Building System is pre-engineered to meet requirements for wind and snow loads in North America. With shelters and buildings in service since 1968, we have truly withstood the test of time.

- Easily repaired: If repair is necessary, the process is simple and requires no specific fiberglass manufacturing expertise.

- Base Mounting: The exterior base flange allows for fastening to various foundations including concrete, steel, wood, asphalt and gravel.

- Options: Designed and manufactured for your building application. Options such as roof hatches, windows, vents, exhaust, HVAC or electrical are all available upon request.

- Expandable: FRP/Mocoat vaulted roof buildings are modular and can be expanded in 4′ segments.