Key Benefits of FRP Mocoat Wastewater Tanks

Lightweight Design for Simple Transport and Installation

One of the standout features of our FRP septic tank in Washington is its lightweight construction. Compared to traditional materials like steel or precast concrete, fiberglass offers significant logistical advantages.

- Faster delivery and handling: The reduced weight allows for easier loading, transportation, and unloading at job sites.

- Minimal heavy equipment: Installation can often be done with smaller machinery, reducing setup costs.

- Ideal for remote access: Lightweight tanks are particularly beneficial for installations in areas where large equipment access is limited, such as forested, mountainous, or rural regions.

This ease of transportation and installation translates into lower operational expenses and faster project timelines – two priorities for engineers and contractors alike.

Corrosion-Resistant and Leak-Proof Construction

Fiberglass-reinforced plastic (FRP) is inherently corrosion-resistant, making it an ideal material for storing human waste and wastewater. Unlike steel tanks that may rust over time or concrete tanks that can crack, FRP septic tanks maintain their structural integrity even after years of exposure to moisture, temperature changes, and chemical waste components.

- No internal corrosion: Prevents breakdown from inside the tank due to waste chemical content.

- No external rusting: Ensures environmental durability even in damp, acidic, or alkaline soils.

- Leak-proof monolithic design: Each tank is moulded as a single seamless unit to eliminate weak points that could leak or crack.

This level of durability significantly reduces the risk of groundwater contamination and expensive system failures.

Certified to CSA Standard B66 for Wastewater Use

FRP Mocoat’s wastewater tanks are fully compliant with CSA Standard B66, the benchmark for septic tanks and wastewater treatment systems in Canada. This standard evaluates:

- Tank strength and design

- Watertight integrity

- Material safety and compatibility with waste content

Our adherence to CSA standards provides added assurance for municipalities, contractors, and homeowners seeking reliable solutions that meet both local and federal requirements in Washington and beyond.

Engineered for Subsurface Pressure and Load

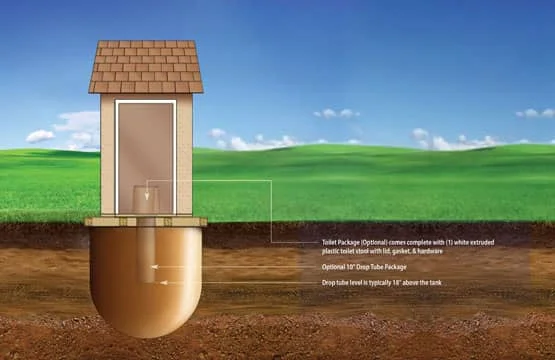

In most installations, septic tanks are buried underground, where they are subjected to the weight of the soil above and the pressure of water tables. FRP Mocoat’s tanks are specifically engineered to withstand up to 2 feet of overburden, meaning they can be safely buried without risk of deformation or collapse.

- High strength-to-weight ratio: Despite their lightness, FRP tanks resist compression and structural fatigue.

- Safe for high-traffic zones: Tanks can be installed beneath lightly loaded surfaces, such as parking areas or landscaping, without fear of compromise.

This built-in strength makes our fiberglass septic tanks in Washington suitable for a wide range of site conditions – from soft loam to compacted clay.

Cost-Efficient for Long-Term Wastewater Management

Initial cost savings are just one part of the value equation. The real return on investment comes from reduced long-term maintenance and replacement costs:

- No rust or decay = fewer repairs over time.

- Seamless, crack-resistant design = virtually zero leakage risk.

- Long product lifespan = fewer replacements across decades of use.

For municipalities and industrial clients, this translates to lower lifecycle costs and greater system reliability. For homeowners and rural property developers, it means peace of mind and fewer unexpected expenses.

Versatile Applications Across Sectors

Our fiberglass tanks are highly versatile, making them suitable for:

- Residential toilet systems

- Off-grid or rural properties

- Municipal wastewater management

- Agricultural operations

- Commercial facilities

- Temporary construction sites

- Seasonal recreational properties (cabins, RV parks, lodges)

Whatever your application, FRP Mocoat can help specify the right FRP septic tank in Washington to meet your operational and environmental requirements.

Why Choose FRP Mocoat? Trusted Fiberglass Septic Tank Manufacturer

When you choose FRP Mocoat, you’re partnering with one of the most experienced fiberglass septic tank manufacturers in North America. We’ve built our reputation on engineering excellence, material integrity, and customer-first service.

Here’s what sets us apart:

- Decades of manufacturing expertise

- Custom tank configurations are available

- Dedicated engineering support for unique site conditions

- CSA B66-certified tanks, made to last

- Responsive customer service and local representation

Unlike mass-market suppliers, we provide tailored, technically sound recommendations backed by decades of practical field experience. Our engineers and support staff are available to assist with specifications, site assessment, regulatory requirements, and installation planning.

Environmental Protection and Sustainability

Environmental concerns are top of mind for municipalities, regulatory bodies, and homeowners alike. Our tanks contribute to sustainability by:

- Preventing wastewater leaks that can contaminate soil and groundwater

- Reducing the frequency of tank replacements, which lowers material waste and environmental disruption

- Minimizing on-site equipment usage, cutting fuel consumption and emissions during installation

With a low carbon footprint and long-lasting design, FRP septic systems are the preferred choice for eco-conscious communities and organizations looking to reduce their environmental impact.

Real-World Use Cases for FRP Septic Tanks in Washington

Rural Farmsteads and Agricultural Developments

Washington’s vast agricultural zones benefit from the corrosion resistance and easy maintenance of FRP septic tanks, especially in areas where livestock waste and farm runoff demand tough, reliable containment systems.

Remote Cabins and Off-Grid Living

For Washingtonians enjoying the serenity of the backcountry, lightweight fiberglass tanks are ideal. They’re easy to deliver and install without needing extensive road access or heavy construction equipment.

Municipal Infrastructure and Parks

Municipalities installing toilet systems in recreation areas, campgrounds, or seasonal facilities can trust FRP tanks for consistent performance and environmental safety.

Commercial Construction Projects

Temporary toilets or mobile office trailers on job sites require reliable wastewater storage – FRP tanks are a fast, compliant solution that won’t break down under pressure.

Where to Order Fiberglass Septic Tanks in Washington?

If you’re looking for fiberglass septic tanks in Washington that combine compliance, efficiency, and performance, FRP Mocoat is your go-to provider. We proudly serve municipalities, contractors, agricultural operations, and residential developers across Washington, Alberta, Saskatchewan, Manitoba, and beyond.

Need Help Choosing the Right Septic Tank?

Whether you’re a civil engineer, municipal procurement officer, or property developer, our team is ready to help you assess your site needs and match you with the ideal FRP septic tank system. From permitting to installation, FRP Mocoat is here to support your success.